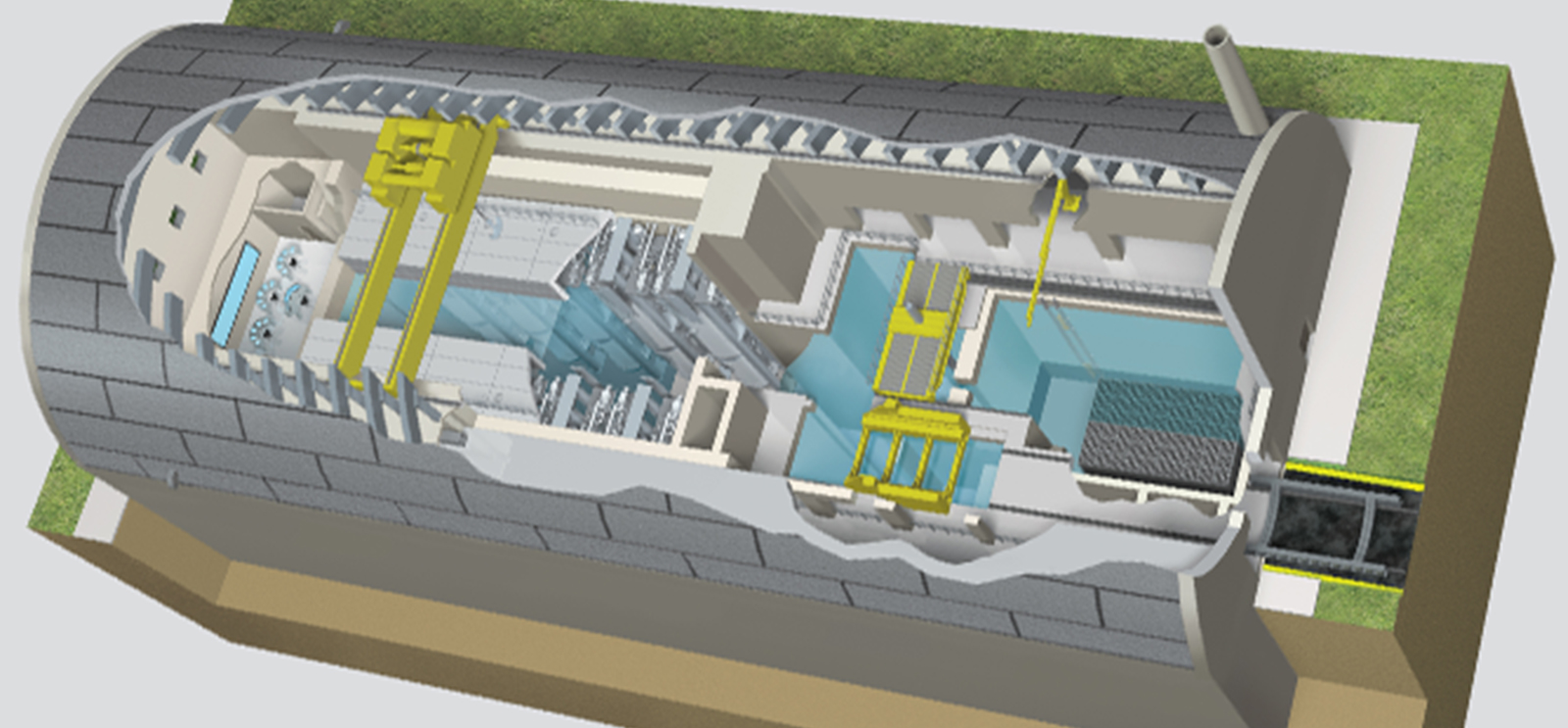

Small modular reactors could energize the nuclear-power industry. (Photo courtesy Nuscale Power)

Small modular nuclear reactors could have economic and safety benefits, a Chicago study reports.

Despite the environmental benefits of nuclear power, two major obstacles have prevented development of the low-carbon energy source: cost and safety. A US Department of Energy–funded study released in December by the Energy Policy Institute at Chicago (EPIC) argues that an emerging technological development, known as a small modular reactor, could go a long way toward mitigating both concerns.

Three to ten times smaller than traditional reactors, modular reactors could reduce the cost of bringing a plant online by 25–50 percent, estimates report coauthor Robert Rosner, institute director and the William E. Wrather distinguished service professor in astronomy and astrophysics. The report, which Rosner wrote with Argonne National Laboratory’s Stephen Goldberg, calls the proposed transition to the new reactors an “evolutionary, rather than a disruptive, radical shift” in nuclear-energy technology.

From a business standpoint, the new technology could revolutionize a stalled industry. The EPIC study notes that developing small modular reactors offers an opportunity for the United States to seize the lead in nuclear manufacturing. The Obama administration apparently agrees, announcing in January that the Department of Energy will allocate $452 million over the next five years for design development.

The price tag of bringing a traditional plant from design to operation—about $2 billion, according to a 2008 Congressional Budget Office report—has deterred nuclear development. There are 31 states with traditional plants in operation and seven states where nuclear power accounts for the largest percentage of electricity generated. But the last US commercial plant to come online was Tennessee’s Watts Bar 1 plant in 1996.

A typical traditional station, Watts Bar generates about 1,123 megawatts of electricity. Nebraska’s Fort Calhoun plant, with an output of 478 megawatts, is the nation’s smallest operational plant. By comparison, small modular reactors would generate between 45 and 300 megawatts. Most of the Energy Policy Institute’s conclusions were based on a hypothetical “middle position” 100 megawatt plant.

“The economic question is all about, ‘Is what I am buying affordable?’” says Rosner. “Are you going to go broke buying it or not? And can you make money when you actually use it?”

The new reactors could be built more quickly and efficiently than traditional plants, although pinpointing precise construction timetables is difficult at this stage. Because traditional plants are built so infrequently, laborers must be trained from scratch with each project, rather than moving from job to job. The proposed small modular reactor industry could change that model. Rosner compares it to the plane and ship industries: “Training costs are sharply reduced and the error rate is sharply reduced. People are just better at what they do.”

It will take time to get laborers up to speed. The learning curve will make the early units expensive enough, Rosner says, that it may be difficult to find initial investors. “Most likely, it is the federal government that will have to be the first major buyer,” he says. Rosner’s optimistic estimate is that, if both the industry and the government push development, the first small modular reactors could become operational in eight to ten years. Realistically, he added, it could be well after 2020 before the first ones come online.

From a safety standpoint, the design of small modular reactors would prevent the problems that plagued Japan’s Fukushima nuclear plant. Small modular reactors were a goal before the Japan disaster, but after the meltdown safety concerns became a major public issue, and researchers like Rosner and Goldberg addressed safety more vigorously. “While the focus in this paper is on the business case for SMRs,” the report notes, “the safety case also is an important element.”

The Japan meltdown occurred when electricity to the plant was cut off as a result of the March 2011 earthquake and tsunami. The small modular reactors’ integrated design eliminates the need for outside electricity. According to the report, the design relies on “robust battery power to maintain minimal safety operations.”

The reactors, says Rosner, also would not be as vulnerable to terrorism because they would be located underground: “There is nothing above ground to attack.”