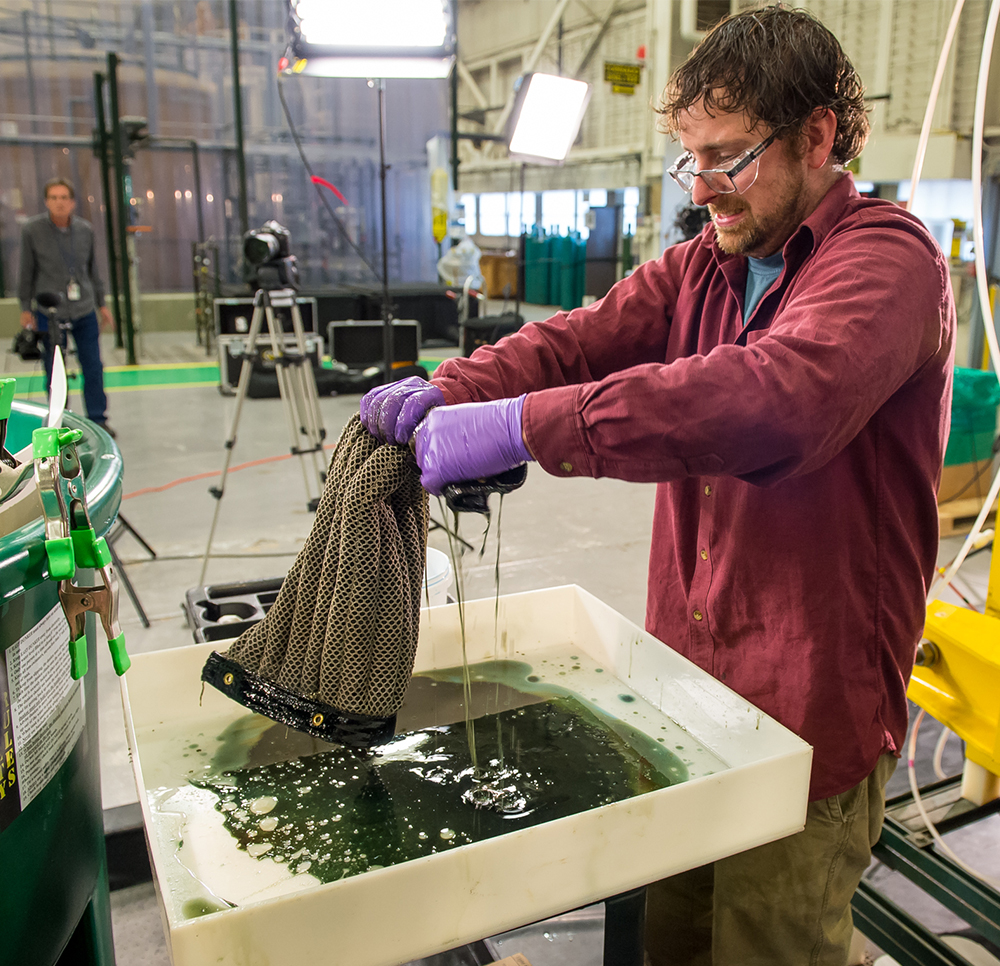

(Photography by Mark Lopez/Argonne National Laboratory)

A new material developed by Argonne scientists could revolutionize oil spill cleanup.

The 2010 Deepwater Horizon oil spill was devastating both because of its size—some 134 million gallons of crude bled into the Gulf of Mexico—and its form. The leaking oil didn’t just remain a slick floating on the ocean’s surface. Instead it formed plumes that sank deep into the water column, where existing cleanup and containment methods, such as skimming, controlled burns, and physical barriers called booms, couldn’t capture it.

That’s what pushed scientists at Argonne National Laboratory to develop a type of foam that collects oil both on and beneath the ocean’s surface. Called the Oleo Sponge, the new material can absorb 90 times its own weight. And not only is the sponge itself reusable, the oil it captures can be wrung out and reclaimed. Seth Darling, a scientist with Argonne’s Center for Nanoscale Materials, a fellow of the UChicago Institute for Molecular Engineering, and one of the inventors of the Oleo Sponge, said the material “offers a set of possibilities that, as far as we know, are unprecedented.”

The sponge consists of foam coated in oleophilic, or “oil-loving,” molecules. To bind the two together, Darling and his collaborator Jeff Elam, a chemist at Argonne, used a technique they developed called sequential infiltration synthesis. SIS allowed the researchers to grow a layer of metal oxide on the foam’s interior surface that acts as a glue for the oil-loving molecules. The result is a material that’s highly absorbent and durable—the Oleo Sponge can be used hundreds of times without breaking down.

In December 2016, the Oleo Sponge was put to the test in a massive saltwater tank at the National Oil Spill Response Research and Renewable Energy Test Facility in Leonardo, New Jersey, where it lapped up underwater crude and diesel oil with no trouble. Now the team is working to commercialize the product in hopes of making it more widely available within the next five years.